The Store

We will remember your selection.

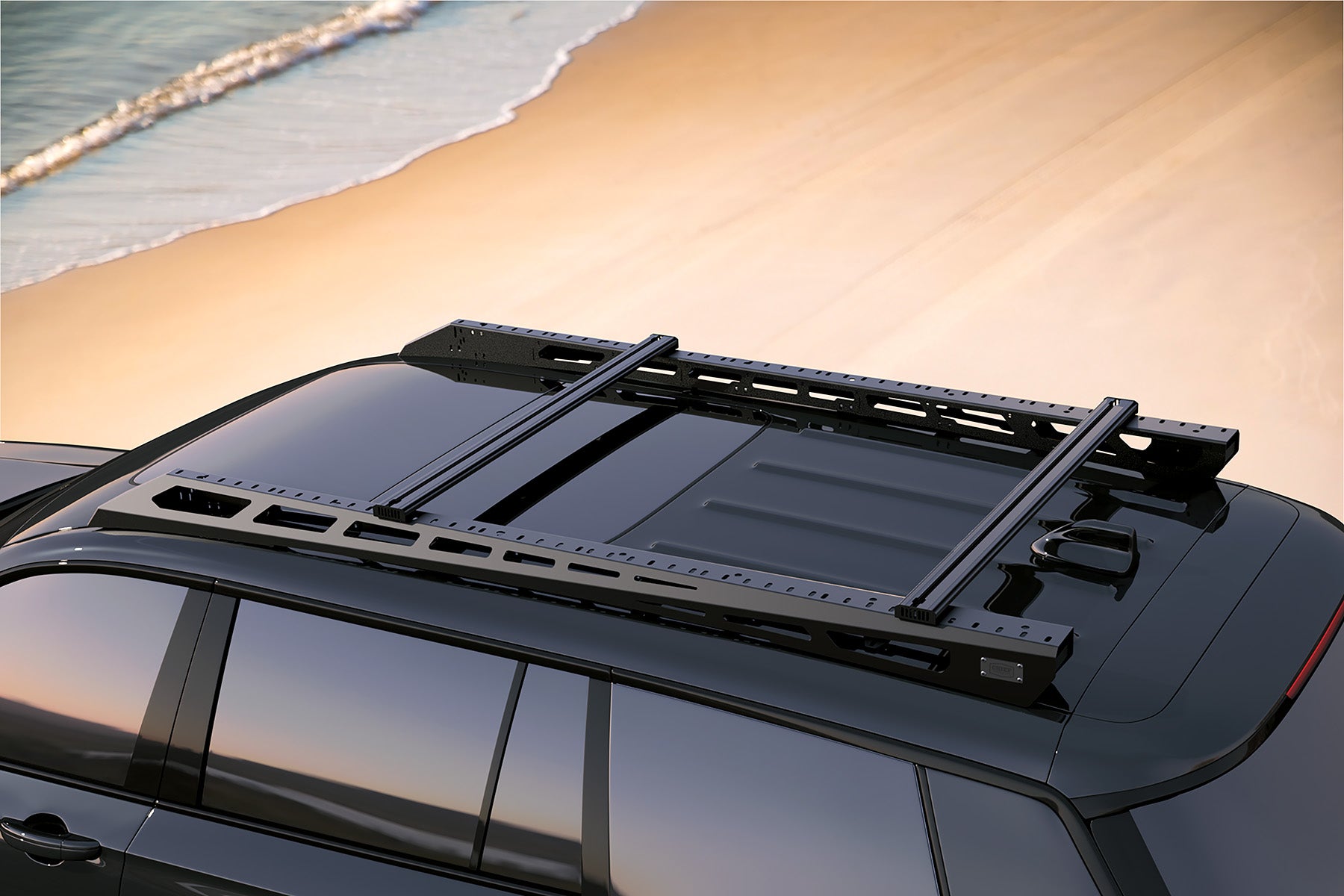

AM2G ROOF RACK

$639.99 AUD

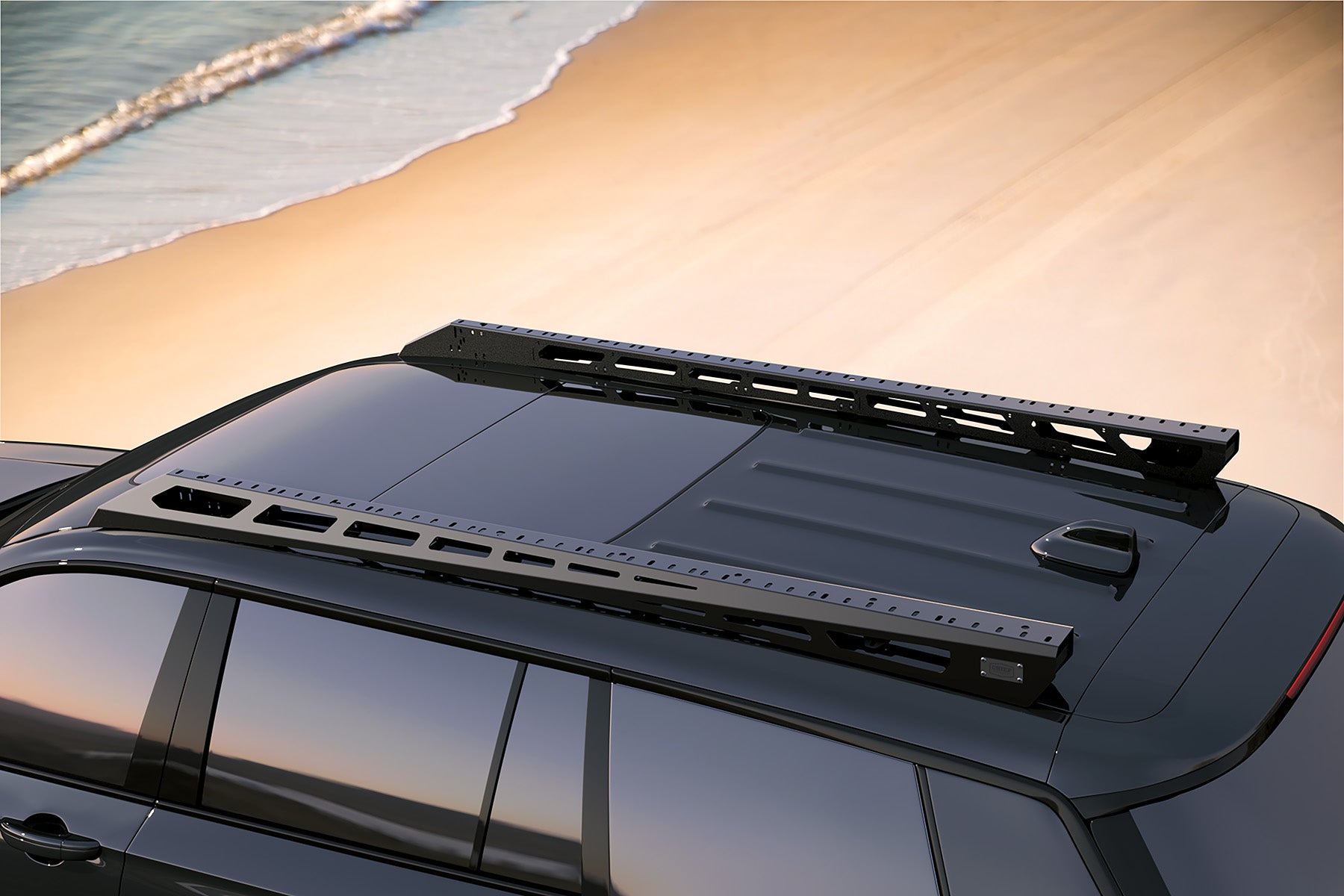

Chief Products AM2G Roof Rack provides the pinnacle of performance for roof rack systems on the AM2G (VW Amarok, 2022-Current). It delivers industry-leading load ratings (150kg dynamic & 460kg static) and vehicle specific styling in a light-weight, low-profile design. Our Modular Roof Rack System provides an unrivalled amount of configurability. Customers can build the roof rack they want, and easily reconfigure it whenever their needs change. One configuration for around town (surfing-kayaking-mountain biking). Then easily change to another configuration for camping-expedition-overlanding (maximum gear, roof top tent, etc.). One roof rack; that can easily adapt to your needs.

-

Chief Products AM2G Roof Rack provides the pinnacle of performance for roof rack systems on the AM2G (VW Amarok, 2022-Current). It delivers industry-leading load ratings (150kg dynamic & 460kg static) and vehicle specific styling in a light-weight, low-profile design. Our Modular Roof Rack System provides an unrivalled amount of configurability. Customers can build the roof rack they want, and easily reconfigure it whenever their needs change. One configuration for around town (surfing-kayaking-mountain biking). Then easily change to another configuration for camping-expedition-overlanding (maximum gear, roof top tent, etc.). One roof rack; that can easily adapt to your needs.

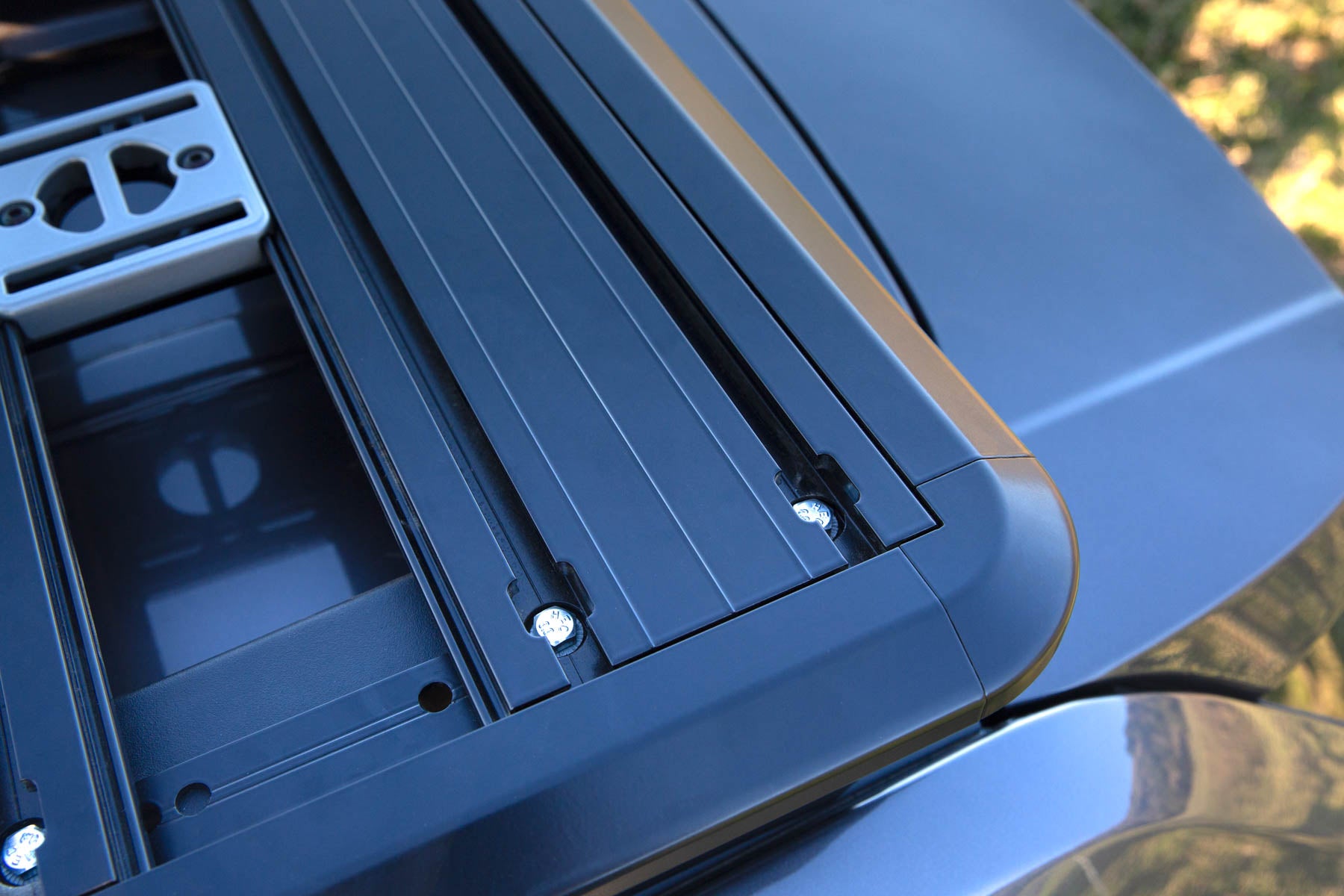

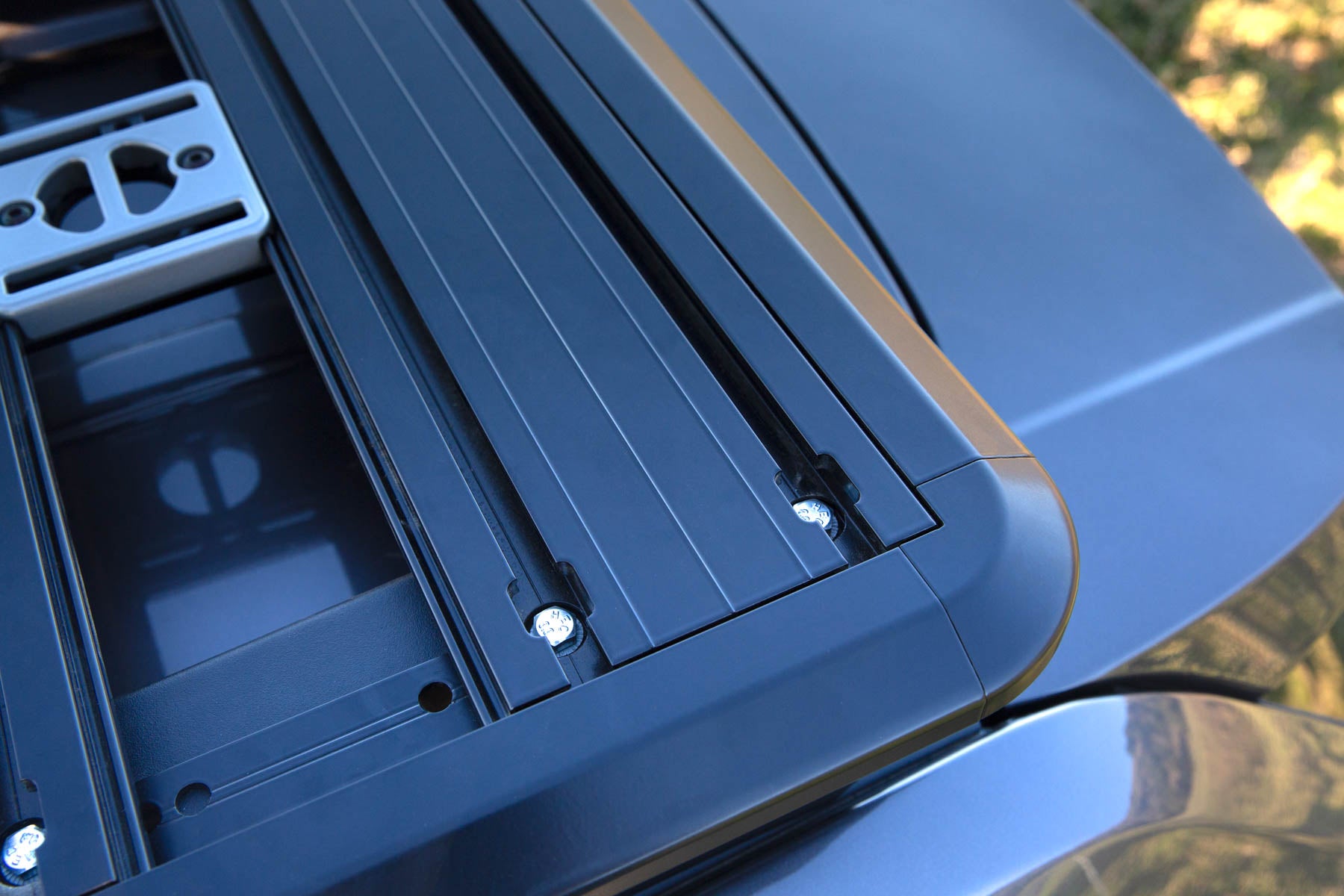

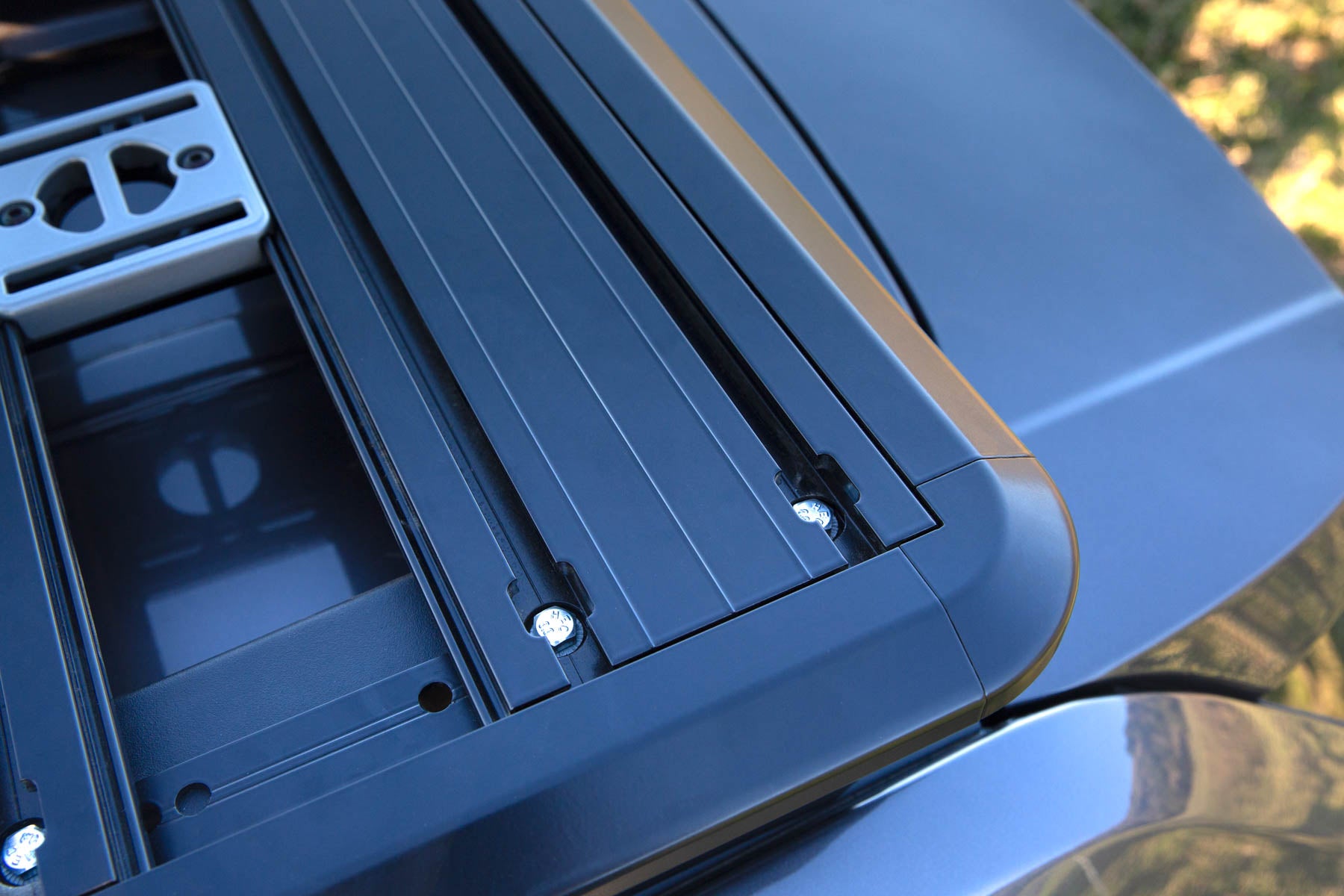

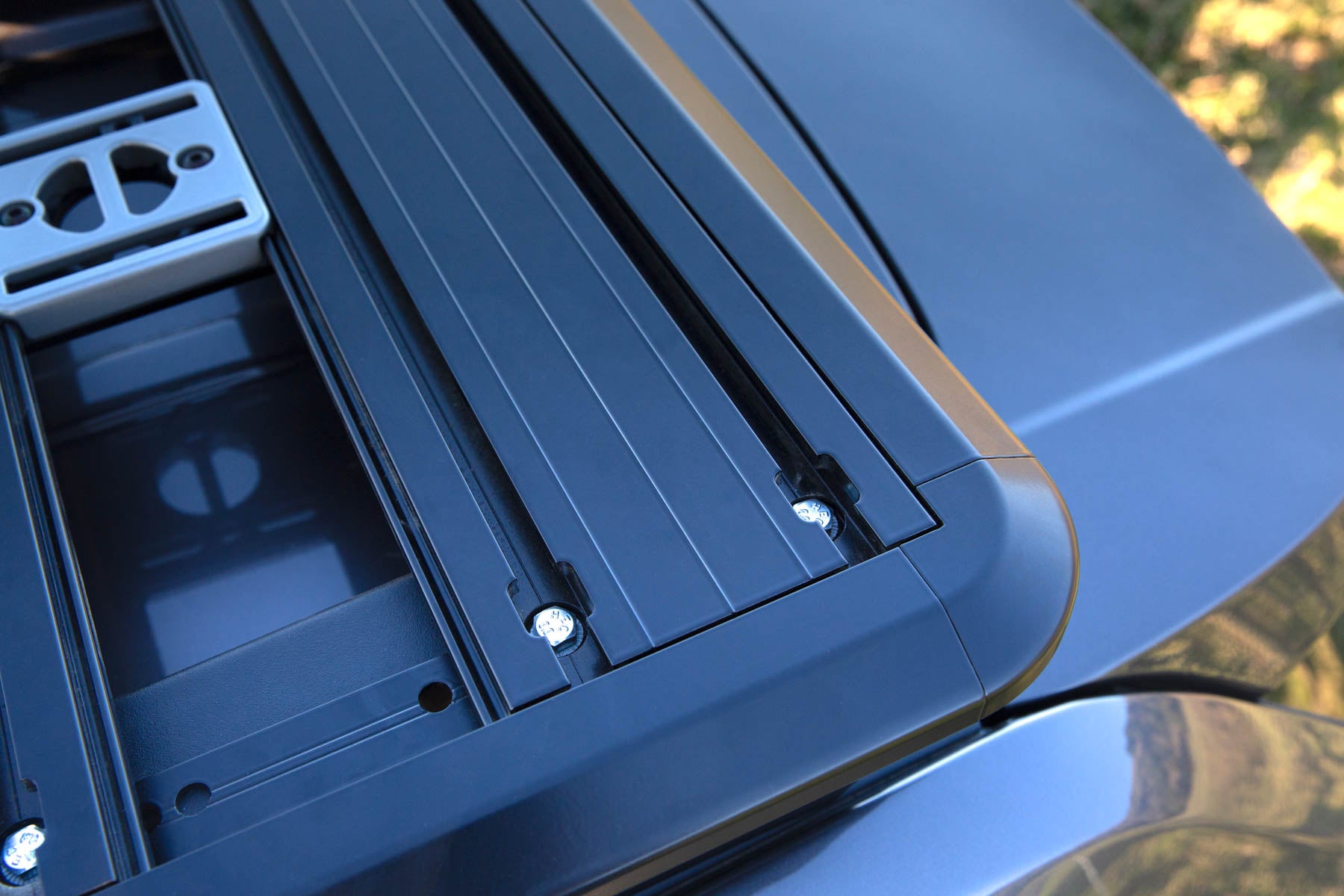

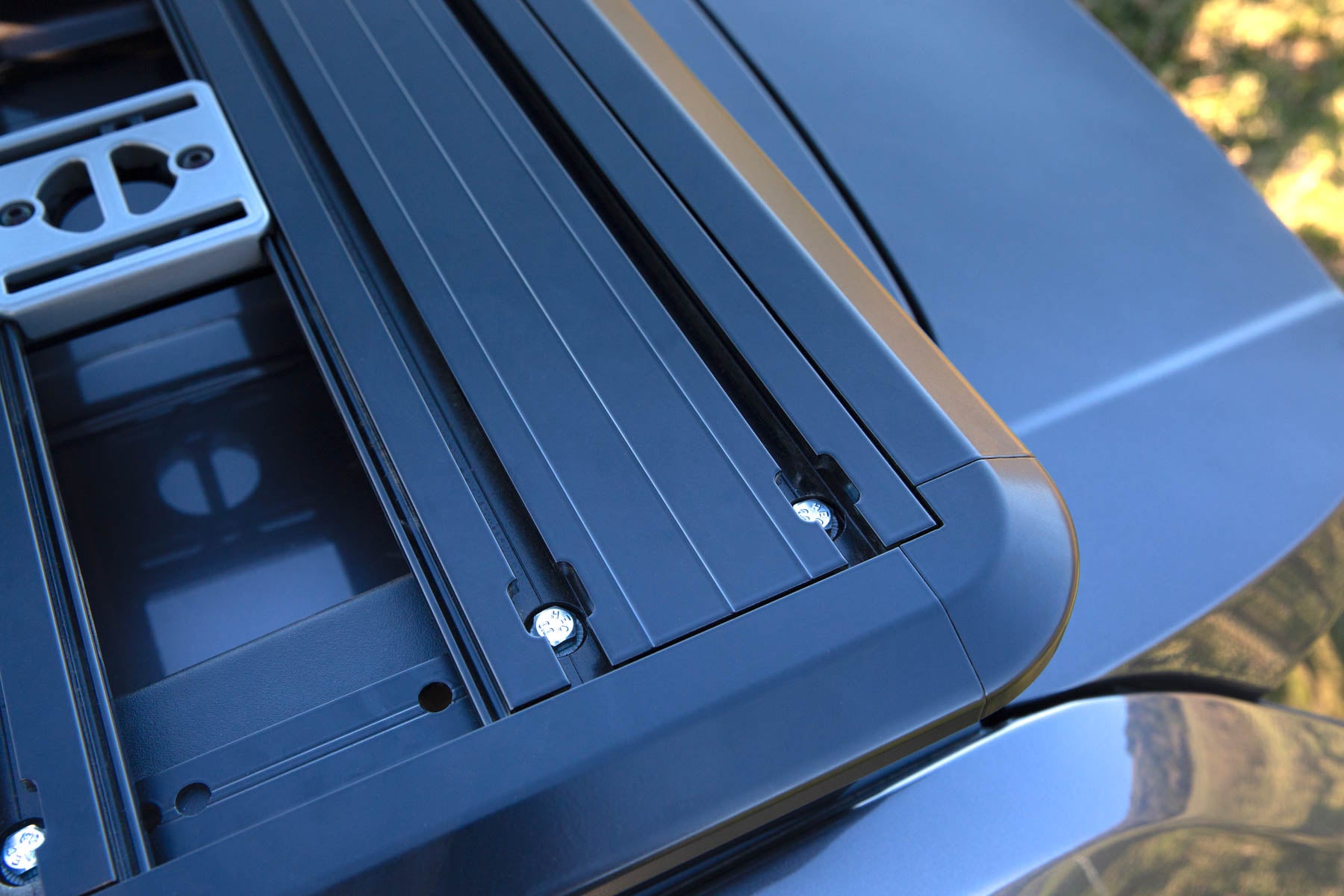

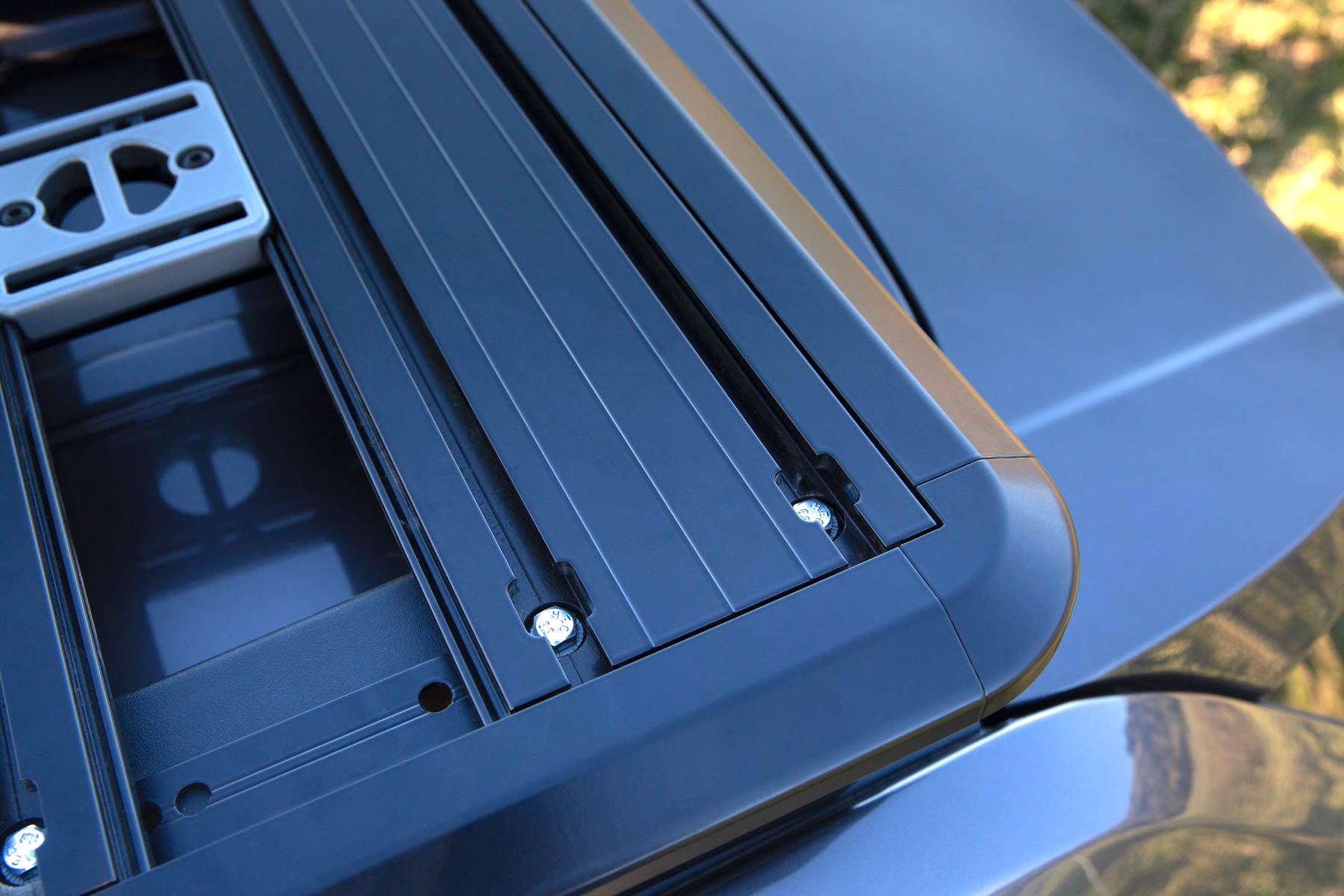

We've utilised the latest manufacturing techniques and aircraft-grade aluminium alloys to keep the overall installed weight low and accomplish a degree of fit-and-finish you have to see in person to truly appreciate. The smooth top surface, low profile design and hidden fasteners have enabled us to deliver an extremely aerodynamic roof rack. Amazingly, even after thousands of kilometres of off-road driving, you won't hear any creaking or rattling. Best of all, we made it extremely easy to mount accessories - whether you're using t-nuts that slide the entire length of the Planks; or our industry-leading Tie-Down Plates that easily slide and clamp between the Planks. If you're looking for a top-quality place to carry extra gear on your next adventure, there's no doubt we've got you covered.

FEATURESMODULAR DESIGN (Mix-And-Match Components)GROUNDBREAKING CONFIGURABILITY (Easily Move & Change Components)HIGH-STRENGTH (Industry-Leading Load Ratings)TOP-QUALITY MATERIALS (Aircraft-Grade Aluminium Alloys + High-Strength Steel)INDUSTRY-LEADING DURABILITY (High-Strength + Corrosion Protection + UV Stable Coatings)INDUSTRY-LEADING CORROSION PROTECTION (Special Coatings, Materials & Hardware)EASILY MOUNT ACCESSORIES (Adjustable Planks, T-Nuts & Tie-Down Plates)PREMIUM ACCESSORIES (Top-Quality, Innovative & 3rd Party Compatibility)VEHICLE SPECIFIC STYLING (Mounting Rails & Aero)STEALTH (Low Wind Noise + No Creaking/Rattling + Unobstructed Sunroof + Stealth Air Dam)TOP QUALITY FASTENERS (Blackened Stainless or High-Tensile + Wedge-Lock Washers)FIT & FINISH (Precision Manufacturing + Unrivalled QC Processes)EASY INSTALLATION (Difficulty = 2/10)SPECIFICATIONS100kg DYNAMIC LOAD RATING (with 2x Half-Planks) 300kg STATIC LOAD RATING (with 2x Half-Planks) 150kg DYNAMIC LOAD RATING (with 2+ Planks) 460kg STATIC LOAD RATING (with 2+ Planks) 86mm OVERALL HEIGHT (above roof line) 25mm PLANK THICKNESS 28.34mm PLATFORM THICKNESS (fully assembled) 1490mm FULL PLATFORM LENGTH (fully assembled) 1246mm FULL PLATFORM WIDTH (fully assembled) 10.4kg INSTALLED WEIGHT --> Bare Bones 10.4kg INSTALLED WEIGHT --> Roof Top Tent [100-300kg] 14.3kg INSTALLED WEIGHT --> Roof Top Tent [150-460kg] 18.2kg INSTALLED WEIGHT --> Overland 24.6kg INSTALLED WEIGHT --> Safari 29.0kg INSTALLED WEIGHT --> Apex 7.1kg INSTALLED WEIGHT --> ((Build Your Own)) INCLUDESBARE BONES

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Half-Planks) [1146mm] 1 ROOF RACK (4x Half-Plank End-Caps) 1 Installation Instructions ROOF TOP TENT [100-300kg]

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Half-Planks) [1146mm] 1 ROOF RACK (4x Half-Plank End-Caps) 1 Installation Instructions ROOF TOP TENT [150-460kg]

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Planks) [1146mm] 1 ROOF RACK (4x Plank End-Caps) 1 ROOF RACK (Roof Top Tent KIT) 1 Installation Instructions OVERLAND

SAFARI

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 3 ROOF RACK (2x Planks) [1146mm] 3 ROOF RACK (4x Plank End-Caps) 1 Installation Instructions APEX

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 3 ROOF RACK (2x Planks) [1146mm] 1 ROOF RACK (Platform Frame) [6 Plank] 1 Installation Instructions ((BUILD YOUR OWN))

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 Installation Instructions EDITIONS* WARNING *

FOR MAXIMUM SAFETY DO NOT EXCEED MANUFACTURERS ROOF WEIGHT LIMITS. Our load ratings represent the maximum mechanical forces our roof rack system can withstand before failure. Our load ratings do not address vehicle safety during high-speed manoeuvres, or changes to vehicle dynamics caused by a higher centre of gravity.

* CAUTION *

For maximum safety, loads should be evenly distributed and properly secured to avoid shifting during transport. Before using your roof rack, it is important to familiarise yourself with the proper load securing techniques and be constantly safety oriented. Please note, all of our load ratings are based on an evenly distributed load. -

UNPRECEDENTED CONFIGURABILITYChoose how many Planks you want. Position your Planks wherever you want. Move your Planks easily, whenever you want. Choose if you want a frame around the outside. Choose how many Tie-Down Plates you want, and where you want them located. Configure your rack however you want. Numerous options. Numerous configurations.

MODULAR DESIGNOur modular engineering approach allow us to deliver a roof rack system that can be easily adapted to any situation. It also means you can upgrade-downgrade your roof rack any time your needs require.

HIGH-STRENGTHAll versions deliver industry leading load ratings. These ratings were independently tested and the test results are certified to comply with Australian Standard (AS 1235-2000) as well as international standards (ISO / PAS 11154 : 2009:2006) and (DIN 75302/02: 1991). During independent testing, our roof rack system successfully withstood 330kg of upward force, 600kg of forward force (including a special 20° off-axis test). To achieve our certification we needed to have less than 10mm of movement in our structure at the tested loads, we had 0.17mm!

One of the keys to our industry leading load ratings is our Mounting Rails. Not only do they transfer forces to the strongest points on the vehicle roof, they also utilise a boxed design that resists deformation at any singular point. This unique design element creates a 'mounting system’ that is much stronger than any of our competitors.

LOW WEIGHTWe utilise the latest manufacturing techniques and aircraft-grade aluminium alloys to deliver a roof rack system with an extremely high strength-to-weight ratio. This means our roof rack has an extremely low weight, while still being the very strongest on the market.

STEALTHChief Products roof racks are engineered to be extremely aerodynamic (smooth top surface, low profile design and hidden fasteners). These unique aerodynamic features make our roof racks extremely quiet for the majority of our customers. However, the more wind you have the more wind noise will increase. For customers that live in high-wind areas or regularly drive at high-speeds (120kmh+) we've developed a Stealth Air Dam (included with every set of Mounting Rails) that significantly reduces the noise caused by high-velocity air flows. Best of all, this wind noise performance improvement is accomplished utilising a product that mounts out-of-sight (ensuring it doesn't inhibit use of your rack, or obscure views out of your sunroof).

Our roof racks deliver an experience with no creaking, no rattling, and very low wind noise. We accomplish these amazing feats through a series of technologically advanced aerodynamic methods, along with some proven old school tech (rubber isolators).

LOW PROFILEOur roof racks are engineered to sit incredibly low at only 86mm above the roofline. We looked at mounting even closer to the vehicle, but during our real-world testing we found it was helpful to have a slight gap between the roof and the rack, so you can slip a hand underneath the rack to wash your roof.

UNOBSTRUCTED VIEWSIf your vehicle has a Sunroof, our roof rack won’t block your view (position your Planks wherever you want) so you can see and experience the beauty of the nature around you.

STYLEWe poured over every design detail to ensure the AM2G Roof Rack would look great from every angle. Function was our primary aim, but we also studied every line and every proportion, paying close attention to how they integrate with the lines of the AM2G.

FIT & FINISHWe utilise advanced manufacturing techniques to achieve a degree of fit-and-finish you have to see in-person to truly appreciate.

SMOOTH TOP SURFACEThe top of our platform is completely smooth. No bolt heads sticking up, tie-down plates that sit completely flush and fasteners that are hidden from view.

EASILY MOUNT ACCESSORIESWe make it extremely easy to mount your accessories and bring your gear with you. We provide (2) full-length channels in each plank, enabling you to use T-Nuts that slide the entire length of the Planks. Even better, is our industry leading Tie-Down Plates and Anchor Points. They provide numerous mounting options and easily slide and clamp between the Planks.

TIE-DOWN PLATESOne of the primary usability goals for our roof racks, was that you could easily bolt/fasten/tie-down to the rack at almost any location. Our custom engineered Tie-Down Plates deliver on that goal. They clamp securely between the Planks in a way that allows them to easily move and fasten anywhere along the entire length of the Planks. The centre acts as an easy tie-down location, while the slots on either end hold captive T-Nuts (M6, M8 & M10) that can be used to fasten/bolt just about any accessory you can find. Best of all, when clamped in place they sit completely flush, providing a completely smooth top surface for your platform.

NEARLY UNLIMITED ACCESSORY MOUNTING LOCATIONSWe provide heaps of mounting locations so you can easily mount accessories anywhere. To achieve that goal, we've engineered Planks you can move wherever you need them. Then we've provided two full-length channels in each Plank for captive T-Nuts, allowing you to bolt/fasten to the Plank at any point along the entire length of the Plank. Finally, for maximum flexibility we've delivered Tie-Down Plates that can easily move and fasten anywhere along the entire length of the Planks.

COMPATIBLE WITH MOST ACCESSORIESIf the accessory uses M6, M8 or M10 bolts for mounting, it will probably work with our roof rack system. If not, one of our upcoming adapter kits should take care of business.

INNOVATIVE SUITE OF ACCESSORIESChief Products engineering team has already started work on several innovative accessories to further expand the functionality of our roof rack system. Taking advantage of our ground-up approach and modular design is allowing us to develop roof rack accessories that no one has ever seen before.

INDUSTRY LEADING CORROSION PROTECTIONWe utilise aircraft-grade aluminium alloys (highly corrosion resistant) for all of the major components of our roof rack system (with a layer of UV stable highly durable powder coat to provide additional protection). For all of our steel parts we utilise E-Coat (Electrophoretic Coating) to provide the very highest corrosion protection available for steel automotive parts, then we add a layer of UV stable powder coat on top for additional protection. All of the included fasteners are protected as well - black zinc plating, zinc flake coatings, black oxide coatings or sometimes we just choose to use stainless steel fasteners. Our aim is to keep your roof rack looking great for many years to come.

EASY TO INSTALLEasy bolt-on installation with no drilling. In addition, our bracketry is fully adjustable so it adapts to your roof.

TOP QUALITY FINISHING TOUCHESWe include all the details that matter. High tensile bolts for maximum strength. Wedge-Lock washers to create bolted joints that are extremely resistant to loosening (critical to combat loosening from off-roading vibrations). Anti-Seize for bolted joints that are resistant to seizing (important for a product that sits on your roof fully exposed to the elements). A Chief Products Shop Rag for all the dirty jobs around the garage. All packaged with extreme care to arrive safely and looking great.

We even include a few details you might not appreciate right away. For instance, if you’re installing lights, we provide channels in our mounting rails to run your wiring, (we even provide small holes for your zip ties, so you can hold your wiring up out of sight). -

Requires drilling (8) holes in the roof gutter to install stainless steel nutserts.Fitment confirmed on the following vehicles:2022 VW Amarok2023 VW Amarok2024 VW AmarokCompatible with the following products:This list is based on customer reports, Chief Products has not confirmed fitment of these products. This list will be updated regularly as customers report their experiences.INSTALLATION INSTRUCTIONS

HAWSE WINCH FAIRLEAD

$109.99 AUD

Chief Products Hawse Winch Fairlead delivers slim lines, large smooth radiuses (perfect for synthetic ropes) and a mirror polish finish. For maximum strength each fairlead is CNC machined from a solid billet of 6061 T6 Aluminium. We then perform high-speed machine polishing to ensure every surface is smooth and radiant. As a final process to protect the finish and deliver maximum protection from the elements, each fairlead receives 20µm of Type II Anodising. To truly appreciate the quality workmanship, you need to hold one in your hand. Best of all, we provide (2) colours so you can choose the style that looks best on your machine.

Chief Products Hawse Winch Fairlead delivers slim lines, large smooth radiuses (perfect for synthetic ropes) and a mirror polish finish. For maximum strength each fairlead is CNC machined from a solid billet of 6061 T6 Aluminium. We then perform high-speed machine polishing to ensure every surface is smooth and radiant. As a final process to protect the finish and deliver maximum protection from the elements, each fairlead receives 20µm of Type II Anodising. To truly appreciate the quality workmanship, you need to hold one in your hand. Best of all, we provide (2) colours so you can choose the style that looks best on your machine.

| 1.1kg | INSTALLED WEIGHT |

| 295.5mm | TOTAL WIDTH (11.63 inches) |

| 70mm | TOTAL HEIGHT (2.76 inches) |

| 29mm | TOTAL DEPTH (1.14 inches) |

| 1 | Hawse Winch Fairlead (6061 T6 Aluminium) |

| 2 | M12 x 30mm High Tensile (12.9) Socket Head Bolts (Zinc Plated) |

J150 ROOF RACK

$769.99 AUD

Chief Products J150 Roof Rack provides the pinnacle of performance for roof rack systems on the J150 (Toyota Prado, 2010-2024). It delivers industry-leading load ratings (150kg dynamic & 460kg static) and vehicle specific styling in a light-weight, low-profile design. Our Modular Roof Rack System provides an unrivalled amount of configurability. Customers can build the roof rack they want, and easily reconfigure it whenever their needs change. One configuration for around town (surfing-kayaking-mountain biking). Then easily change to another configuration for camping-expedition-overlanding (maximum gear, roof top tent, etc.). One roof rack; that can easily adapt to your needs.

-

Chief Products J150 Roof Rack provides the pinnacle of performance for roof rack systems on the J150 (Toyota Prado, 2010-2024). It delivers industry-leading load ratings (150kg dynamic & 460kg static) and vehicle specific styling in a light-weight, low-profile design. Our Modular Roof Rack System provides an unrivalled amount of configurability. Customers can build the roof rack they want, and easily reconfigure it whenever their needs change. One configuration for around town (surfing-kayaking-mountain biking). Then easily change to another configuration for camping-expedition-overlanding (maximum gear, roof top tent, etc.). One roof rack; that can easily adapt to your needs.

We've utilised the latest manufacturing techniques and aircraft-grade aluminium alloys to keep the overall installed weight low and accomplish a degree of fit-and-finish you have to see in person to truly appreciate. The smooth top surface, low profile design and hidden fasteners have enabled us to deliver an extremely aerodynamic roof rack. Amazingly, even after thousands of kilometres of off-road driving, you won't hear any creaking or rattling. Best of all, we made it extremely easy to mount accessories - whether you're using t-nuts that slide the entire length of the Planks; or our industry-leading Tie-Down Plates that easily slide and clamp between the Planks. If you're looking for a top-quality place to carry extra gear on your next adventure, there's no doubt we've got you covered.

FEATURESMODULAR DESIGN (Mix-And-Match Components)GROUNDBREAKING CONFIGURABILITY (Easily Move & Change Components)HIGH-STRENGTH (Industry-Leading Load Ratings)TOP-QUALITY MATERIALS (Aircraft-Grade Aluminium Alloys + High-Strength Steel)INDUSTRY-LEADING DURABILITY (High-Strength + Corrosion Protection + UV Stable Coatings)INDUSTRY-LEADING CORROSION PROTECTION (Special Coatings, Materials & Hardware)EASILY MOUNT ACCESSORIES (Adjustable Planks, T-Nuts & Tie-Down Plates)PREMIUM ACCESSORIES (Top-Quality, Innovative & 3rd Party Compatibility)VEHICLE SPECIFIC STYLING (Mounting Rails & Aero)STEALTH (Low Wind Noise + No Creaking/Rattling + Unobstructed Sunroof + Stealth Air Dam)TOP QUALITY FASTENERS (Blackened Stainless or High-Tensile + Wedge-Lock Washers)FIT & FINISH (Precision Manufacturing + Unrivalled QC Processes)EASY INSTALLATION (Difficulty = 2/10)SPECIFICATIONS100kg DYNAMIC LOAD RATING (with 2x Half-Planks) 300kg STATIC LOAD RATING (with 2x Half-Planks) 150kg DYNAMIC LOAD RATING (with 2+ Planks) 460kg STATIC LOAD RATING (with 2+ Planks) 86mm OVERALL HEIGHT (above roof line) 25mm PLANK THICKNESS 28.34mm PLATFORM THICKNESS (fully assembled) 1990mm FULL PLATFORM LENGTH (fully assembled) 1246mm FULL PLATFORM WIDTH (fully assembled) 11.4kg INSTALLED WEIGHT --> Bare Bones 11.4kg INSTALLED WEIGHT --> Roof Top Tent [100-300kg] 15.3kg INSTALLED WEIGHT --> Roof Top Tent [150-460kg] 19.2kg INSTALLED WEIGHT --> Overland 30.8kg INSTALLED WEIGHT --> Safari 36.4kg INSTALLED WEIGHT --> Apex 8.1kg INSTALLED WEIGHT --> ((Build Your Own)) INCLUDESBARE BONES

1 J150 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Half-Planks) [1146mm] 1 ROOF RACK (4x Half-Plank End-Caps) 1 Installation Instructions ROOF TOP TENT [100-300kg]

1 J150 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Half-Planks) [1146mm] 1 ROOF RACK (4x Half-Plank End-Caps) 1 Installation Instructions ROOF TOP TENT [150-460kg]

1 J150 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Planks) [1146mm] 1 ROOF RACK (4x Plank End-Caps) 1 ROOF RACK (Roof Top Tent KIT) 1 Installation Instructions OVERLAND

SAFARI

1 J150 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 4 ROOF RACK (2x Planks) [1146mm] 4 ROOF RACK (4x Plank End-Caps) 1 Installation Instructions APEX

1 J150 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 4 ROOF RACK (2x Planks) [1146mm] 1 ROOF RACK (Platform Frame) [8 Plank] 1 Installation Instructions ((BUILD YOUR OWN))

1 J150 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 Installation Instructions EDITIONS* WARNING *

FOR MAXIMUM SAFETY DO NOT EXCEED MANUFACTURERS ROOF WEIGHT LIMITS. Our load ratings represent the maximum mechanical forces our roof rack system can withstand before failure. Our load ratings do not address vehicle safety during high-speed manoeuvres, or changes to vehicle dynamics caused by a higher centre of gravity.

* CAUTION *

For maximum safety, loads should be evenly distributed and properly secured to avoid shifting during transport. Before using your roof rack, it is important to familiarise yourself with the proper load securing techniques and be constantly safety oriented. Please note, all of our load ratings are based on an evenly distributed load. -

UNPRECEDENTED CONFIGURABILITYChoose how many Planks you want. Position your Planks wherever you want. Move your Planks easily, whenever you want. Choose if you want a frame around the outside. Choose how many Tie-Down Plates you want, and where you want them located. Configure your rack however you want. Numerous options. Numerous configurations.

MODULAR DESIGNOur modular engineering approach allow us to deliver a roof rack system that can be easily adapted to any situation. It also means you can upgrade-downgrade your roof rack any time your needs require.

HIGH-STRENGTHAll versions deliver industry leading load ratings. These ratings were independently tested and the test results are certified to comply with Australian Standard (AS 1235-2000) as well as international standards (ISO / PAS 11154 : 2009:2006) and (DIN 75302/02: 1991). During independent testing, our roof rack system successfully withstood 330kg of upward force, 600kg of forward force (including a special 20° off-axis test). To achieve our certification we needed to have less than 10mm of movement in our structure at the tested loads, we had 0.17mm!

One of the keys to our industry leading load ratings is our Mounting Rails. Not only do they transfer forces to the strongest points on the vehicle roof, they also utilise a boxed design that resists deformation at any singular point. This unique design element creates a 'mounting system’ that is much stronger than any of our competitors.

LOW WEIGHTWe utilise the latest manufacturing techniques and aircraft-grade aluminium alloys to deliver a roof rack system with an extremely high strength-to-weight ratio. This means our roof rack has an extremely low weight, while still being the very strongest on the market.

STEALTHChief Products roof racks are engineered to be extremely aerodynamic (smooth top surface, low profile design and hidden fasteners). These unique aerodynamic features make our roof racks extremely quiet for the majority of our customers. However, the more wind you have the more wind noise will increase. For customers that live in high-wind areas or regularly drive at high-speeds (120kmh+) we've developed a Stealth Air Dam (included with every set of Mounting Rails) that significantly reduces the noise caused by high-velocity air flows. Best of all, this wind noise performance improvement is accomplished utilising a product that mounts out-of-sight (ensuring it doesn't inhibit use of your rack, or obscure views out of your sunroof).

Our roof racks deliver an experience with no creaking, no rattling, and very low wind noise. We accomplish these amazing feats through a series of technologically advanced aerodynamic methods, along with some proven old school tech (rubber isolators).

LOW PROFILEOur roof racks are engineered to sit incredibly low at only 86mm above the roofline. We looked at mounting even closer to the vehicle, but during our real-world testing we found it was helpful to have a slight gap between the roof and the rack, so you can slip a hand underneath the rack to wash your roof.

UNOBSTRUCTED VIEWSIf your vehicle has a Sunroof, our roof rack won’t block your view (position your Planks wherever you want) so you can see and experience the beauty of the nature around you.

STYLEWe poured over every design detail to ensure the J150 Roof Rack would look great from every angle. Function was our primary aim, but we also studied every line and every proportion, paying close attention to how they integrate with the lines of the J150.

FIT & FINISHWe utilise advanced manufacturing techniques to achieve a degree of fit-and-finish you have to see in-person to truly appreciate.

SMOOTH TOP SURFACEThe top of our platform is completely smooth. No bolt heads sticking up, tie-down plates that sit completely flush and fasteners that are hidden from view.

EASILY MOUNT ACCESSORIESWe make it extremely easy to mount your accessories and bring your gear with you. We provide (2) full-length channels in each plank, enabling you to use T-Nuts that slide the entire length of the Planks. Even better, is our industry leading Tie-Down Plates and Anchor Points. They provide numerous mounting options and easily slide and clamp between the Planks.

TIE-DOWN PLATESOne of the primary usability goals for our roof racks, was that you could easily bolt/fasten/tie-down to the rack at almost any location. Our custom engineered Tie-Down Plates deliver on that goal. They clamp securely between the Planks in a way that allows them to easily move and fasten anywhere along the entire length of the Planks. The centre acts as an easy tie-down location, while the slots on either end hold captive T-Nuts (M6, M8 & M10) that can be used to fasten/bolt just about any accessory you can find. Best of all, when clamped in place they sit completely flush, providing a completely smooth top surface for your platform.

NEARLY UNLIMITED ACCESSORY MOUNTING LOCATIONSWe provide heaps of mounting locations so you can easily mount accessories anywhere. To achieve that goal, we've engineered Planks you can move wherever you need them. Then we've provided two full-length channels in each Plank for captive T-Nuts, allowing you to bolt/fasten to the Plank at any point along the entire length of the Plank. Finally, for maximum flexibility we've delivered Tie-Down Plates that can easily move and fasten anywhere along the entire length of the Planks.

COMPATIBLE WITH MOST ACCESSORIESIf the accessory uses M6, M8 or M10 bolts for mounting, it will probably work with our roof rack system. If not, one of our upcoming adapter kits should take care of business.

INNOVATIVE SUITE OF ACCESSORIESChief Products engineering team has already started work on several innovative accessories to further expand the functionality of our roof rack system. Taking advantage of our ground-up approach and modular design is allowing us to develop roof rack accessories that no one has ever seen before.

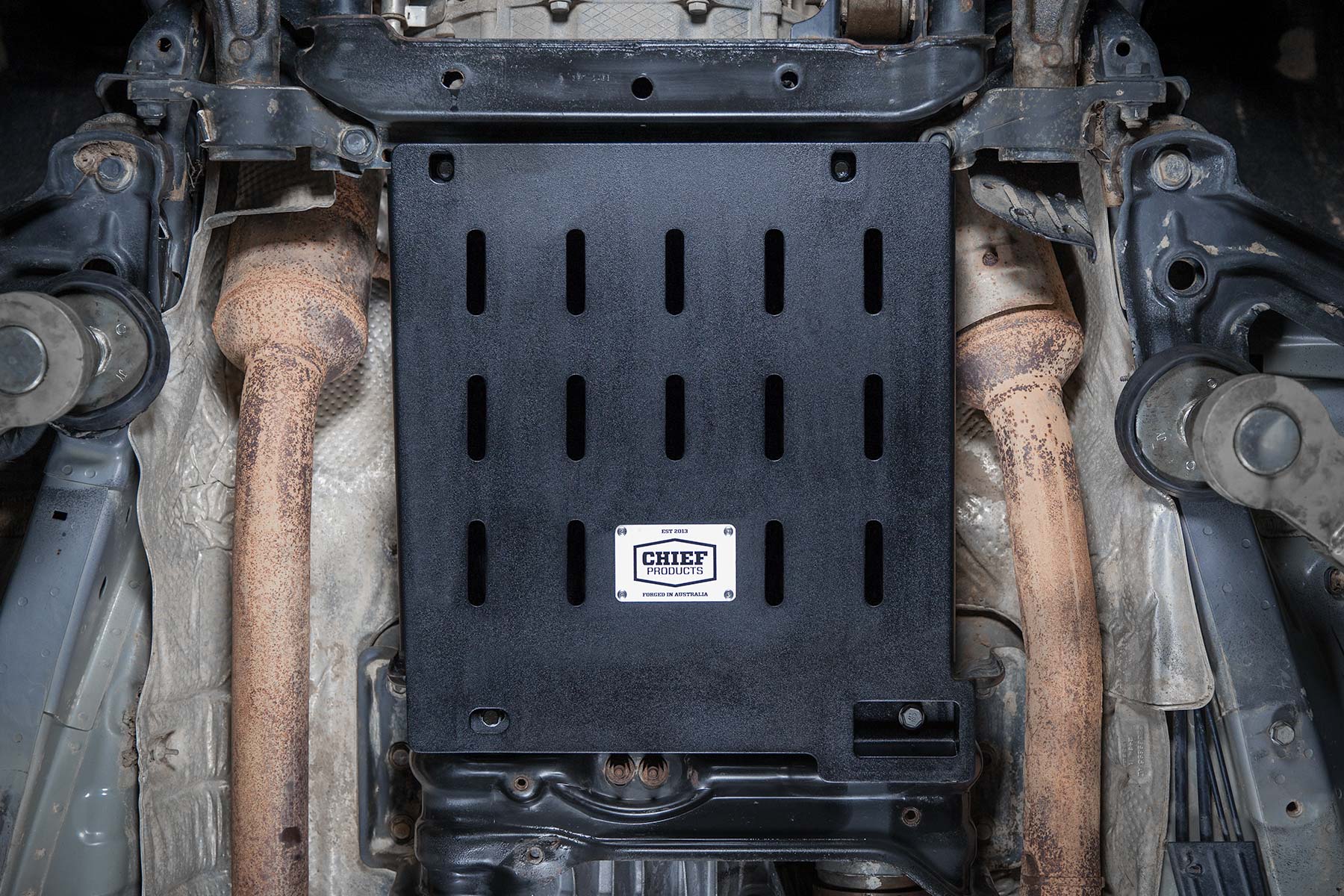

INDUSTRY LEADING CORROSION PROTECTIONWe utilise aircraft-grade aluminium alloys (highly corrosion resistant) for all of the major components of our roof rack system (with a layer of UV stable highly durable powder coat to provide additional protection). For all of our steel parts we utilise E-Coat (Electrophoretic Coating) to provide the very highest corrosion protection available for steel automotive parts, then we add a layer of UV stable powder coat on top for additional protection. All of the included fasteners are protected as well - black zinc plating, zinc flake coatings, black oxide coatings or sometimes we just choose to use stainless steel fasteners. Our aim is to keep your roof rack looking great for many years to come.

EASY TO INSTALLEasy bolt-on installation with no drilling. In addition, our bracketry is fully adjustable so it adapts to your roof.

TOP QUALITY FINISHING TOUCHESWe include all the details that matter. High tensile bolts for maximum strength. Wedge-Lock washers to create bolted joints that are extremely resistant to loosening (critical to combat loosening from off-roading vibrations). Anti-Seize for bolted joints that are resistant to seizing (important for a product that sits on your roof fully exposed to the elements). A Chief Products Shop Rag for all the dirty jobs around the garage. All packaged with extreme care to arrive safely and looking great.

We even include a few details you might not appreciate right away. For instance, if you’re installing lights, we provide channels in our mounting rails to run your wiring, (we even provide small holes for your zip ties, so you can hold your wiring up out of sight). -

No drilling or cutting required. Bolts to the roof using the existing roof nutserts provided by Toyota.Fitment confirmed on the following vehicles:2010 Toyota Prado2011 Toyota Prado2012 Toyota Prado2013 Toyota Prado2014 Toyota Prado2015 Toyota Prado2016 Toyota Prado2017 Toyota Prado2018 Toyota Prado2019 Toyota Prado2020 Toyota Prado2021 Toyota Prado2022 Toyota Prado2023 Toyota Prado2024 Toyota PradoCompatible with the following products:This list is based on customer reports, Chief Products has not confirmed fitment of these products. This list will be updated regularly as customers report their experiences.INSTALLATION INSTRUCTIONS

J200 ROOF RACK

$899.99 AUD

Chief Products J200 Roof Rack provides the pinnacle of performance for roof rack systems on the J200 (Toyota LandCruiser 200, 2008-2021). It delivers industry-leading load ratings (150kg dynamic & 460kg static) and vehicle specific styling in a light-weight, low-profile design. Our Modular Roof Rack System provides an unrivalled amount of configurability. Customers can build the roof rack they want, and easily reconfigure it whenever their needs change. One configuration for around town (surfing-kayaking-mountain biking). Then easily change to another configuration for camping-expedition-overlanding (maximum gear, roof top tent, etc.). One roof rack; that can easily adapt to your needs.

-

Chief Products J200 Roof Rack provides the pinnacle of performance for roof rack systems on the J200 (Toyota LandCruiser 200, 2008-2021). It delivers industry-leading load ratings (150kg dynamic & 460kg static) and vehicle specific styling in a light-weight, low-profile design. Our Modular Roof Rack System provides an unrivalled amount of configurability. Customers can build the roof rack they want, and easily reconfigure it whenever their needs change. One configuration for around town (surfing-kayaking-mountain biking). Then easily change to another configuration for camping-expedition-overlanding (maximum gear, roof top tent, etc.). One roof rack; that can easily adapt to your needs.

We've utilised the latest manufacturing techniques and aircraft-grade aluminium alloys to keep the overall installed weight low and accomplish a degree of fit-and-finish you have to see in person to truly appreciate. The smooth top surface, low profile design and hidden fasteners have enabled us to deliver an extremely aerodynamic roof rack. Amazingly, even after thousands of kilometres of off-road driving, you won't hear any creaking or rattling. Best of all, we made it extremely easy to mount accessories - whether you're using t-nuts that slide the entire length of the Planks; or our industry-leading Tie-Down Plates that easily slide and clamp between the Planks. If you're looking for a top-quality place to carry extra gear on your next adventure, there's no doubt we've got you covered.

FEATURESMODULAR DESIGN (Mix-And-Match Components)GROUNDBREAKING CONFIGURABILITY (Easily Move & Change Components)HIGH-STRENGTH (Industry-Leading Load Ratings)TOP-QUALITY MATERIALS (Aircraft-Grade Aluminium Alloys + High-Strength Steel)INDUSTRY-LEADING DURABILITY (High-Strength + Corrosion Protection + UV Stable Coatings)INDUSTRY-LEADING CORROSION PROTECTION (Special Coatings, Materials & Hardware)EASILY MOUNT ACCESSORIES (Adjustable Planks, T-Nuts & Tie-Down Plates)PREMIUM ACCESSORIES (Top-Quality, Innovative & 3rd Party Compatibility)VEHICLE SPECIFIC STYLING (Mounting Rails & Aero)STEALTH (Low Wind Noise + No Creaking/Rattling + Unobstructed Sunroof + Stealth Air Dam)TOP QUALITY FASTENERS (Blackened Stainless or High-Tensile + Wedge-Lock Washers)FIT & FINISH (Precision Manufacturing + Unrivalled QC Processes)EASY INSTALLATION (Difficulty = 2/10)SPECIFICATIONS100kg DYNAMIC LOAD RATING (with 2x Half-Planks) 300kg STATIC LOAD RATING (with 2x Half-Planks) 150kg DYNAMIC LOAD RATING (with 2+ Planks) 460kg STATIC LOAD RATING (with 2+ Planks) 86mm OVERALL HEIGHT (above roof line) 25mm PLANK THICKNESS 28.34mm PLATFORM THICKNESS (fully assembled) 2160mm FULL PLATFORM LENGTH (fully assembled) 1246mm FULL PLATFORM WIDTH (fully assembled) 14.4kg INSTALLED WEIGHT --> Bare Bones 14.4kg INSTALLED WEIGHT --> Roof Top Tent [100-300kg] 18.3kg INSTALLED WEIGHT --> Roof Top Tent [150-460kg] 22.2kg INSTALLED WEIGHT --> Overland 34.5kg INSTALLED WEIGHT --> Safari 42.7kg INSTALLED WEIGHT --> Apex 11.1kg INSTALLED WEIGHT --> ((Build Your Own)) INCLUDESBARE BONES

1 J200 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Half-Planks) [1146mm] 1 ROOF RACK (4x Half-Plank End-Caps) 1 Installation Instructions ROOF TOP TENT [100-300kg]

1 J200 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Half-Planks) [1146mm] 1 ROOF RACK (4x Half-Plank End-Caps) 1 Installation Instructions ROOF TOP TENT [150-460kg]

1 J200 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Planks) [1146mm] 1 ROOF RACK (4x Plank End-Caps) 1 ROOF RACK (Roof Top Tent KIT) 1 Installation Instructions OVERLAND

SAFARI

1 J200 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 4 ROOF RACK (2x Planks) [1146mm] 4 ROOF RACK (4x Plank End-Caps) 1 ROOF RACK (2x Half-Planks) [1146mm] 1 ROOF RACK (4x Half-Plank End-Caps) 1 Installation Instructions APEX

1 J200 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 4 ROOF RACK (2x Planks) [1146mm] 1 ROOF RACK (2x Half-Planks) [1146mm] 1 ROOF RACK (Platform Frame) [8.5 Plank] 1 Installation Instructions ((BUILD YOUR OWN))

1 J200 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 Installation Instructions EDITIONS* WARNING *

FOR MAXIMUM SAFETY DO NOT EXCEED MANUFACTURERS ROOF WEIGHT LIMITS. Our load ratings represent the maximum mechanical forces our roof rack system can withstand before failure. Our load ratings do not address vehicle safety during high-speed manoeuvres, or changes to vehicle dynamics caused by a higher centre of gravity.

* CAUTION *

For maximum safety, loads should be evenly distributed and properly secured to avoid shifting during transport. Before using your roof rack, it is important to familiarise yourself with the proper load securing techniques and be constantly safety oriented. Please note, all of our load ratings are based on an evenly distributed load. -

UNPRECEDENTED CONFIGURABILITYChoose how many Planks you want. Position your Planks wherever you want. Move your Planks easily, whenever you want. Choose if you want a frame around the outside. Choose how many Tie-Down Plates you want, and where you want them located. Configure your rack however you want. Numerous options. Numerous configurations.

MODULAR DESIGNOur modular engineering approach allow us to deliver a roof rack system that can be easily adapted to any situation. It also means you can upgrade-downgrade your roof rack any time your needs require.

HIGH-STRENGTHAll versions deliver industry leading load ratings. These ratings were independently tested and the test results are certified to comply with Australian Standard (AS 1235-2000) as well as international standards (ISO / PAS 11154 : 2009:2006) and (DIN 75302/02: 1991). During independent testing, our roof rack system successfully withstood 330kg of upward force, 600kg of forward force (including a special 20° off-axis test). To achieve our certification we needed to have less than 10mm of movement in our structure at the tested loads, we had 0.17mm!

One of the keys to our industry leading load ratings is our Mounting Rails. Not only do they transfer forces to the strongest points on the vehicle roof, they also utilise a boxed design that resists deformation at any singular point. This unique design element creates a 'mounting system’ that is much stronger than any of our competitors.

LOW WEIGHTWe utilise the latest manufacturing techniques and aircraft-grade aluminium alloys to deliver a roof rack system with an extremely high strength-to-weight ratio. This means our roof rack has an extremely low weight, while still being the very strongest on the market.

STEALTHChief Products roof racks are engineered to be extremely aerodynamic (smooth top surface, low profile design and hidden fasteners). These unique aerodynamic features make our roof racks extremely quiet for the majority of our customers. However, the more wind you have the more wind noise will increase. For customers that live in high-wind areas or regularly drive at high-speeds (120kmh+) we've developed a Stealth Air Dam (included with every set of Mounting Rails) that significantly reduces the noise caused by high-velocity air flows. Best of all, this wind noise performance improvement is accomplished utilising a product that mounts out-of-sight (ensuring it doesn't inhibit use of your rack, or obscure views out of your sunroof).

Our roof racks deliver an experience with no creaking, no rattling, and very low wind noise. We accomplish these amazing feats through a series of technologically advanced aerodynamic methods, along with some proven old school tech (rubber isolators).

LOW PROFILEOur roof racks are engineered to sit incredibly low at only 86mm above the roofline. We looked at mounting even closer to the vehicle, but during our real-world testing we found it was helpful to have a slight gap between the roof and the rack, so you can slip a hand underneath the rack to wash your roof.

UNOBSTRUCTED VIEWSIf your vehicle has a Sunroof, our roof rack won’t block your view (position your Planks wherever you want) so you can see and experience the beauty of the nature around you.

STYLEWe poured over every design detail to ensure the J200 Roof Rack would look great from every angle. Function was our primary aim, but we also studied every line and every proportion, paying close attention to how they integrate with the lines of the J200.

FIT & FINISHWe utilise advanced manufacturing techniques to achieve a degree of fit-and-finish you have to see in-person to truly appreciate.

SMOOTH TOP SURFACEThe top of our platform is completely smooth. No bolt heads sticking up, tie-down plates that sit completely flush and fasteners that are hidden from view.

EASILY MOUNT ACCESSORIESWe make it extremely easy to mount your accessories and bring your gear with you. We provide (2) full-length channels in each plank, enabling you to use T-Nuts that slide the entire length of the Planks. Even better, is our industry leading Tie-Down Plates and Anchor Points. They provide numerous mounting options and easily slide and clamp between the Planks.

TIE-DOWN PLATESOne of the primary usability goals for our roof racks, was that you could easily bolt/fasten/tie-down to the rack at almost any location. Our custom engineered Tie-Down Plates deliver on that goal. They clamp securely between the Planks in a way that allows them to easily move and fasten anywhere along the entire length of the Planks. The centre acts as an easy tie-down location, while the slots on either end hold captive T-Nuts (M6, M8 & M10) that can be used to fasten/bolt just about any accessory you can find. Best of all, when clamped in place they sit completely flush, providing a completely smooth top surface for your platform.

NEARLY UNLIMITED ACCESSORY MOUNTING LOCATIONSWe provide heaps of mounting locations so you can easily mount accessories anywhere. To achieve that goal, we've engineered Planks you can move wherever you need them. Then we've provided two full-length channels in each Plank for captive T-Nuts, allowing you to bolt/fasten to the Plank at any point along the entire length of the Plank. Finally, for maximum flexibility we've delivered Tie-Down Plates that can easily move and fasten anywhere along the entire length of the Planks.

COMPATIBLE WITH MOST ACCESSORIESIf the accessory uses M6, M8 or M10 bolts for mounting, it will probably work with our roof rack system. If not, one of our upcoming adapter kits should take care of business.

INNOVATIVE SUITE OF ACCESSORIESChief Products engineering team has already started work on several innovative accessories to further expand the functionality of our roof rack system. Taking advantage of our ground-up approach and modular design is allowing us to develop roof rack accessories that no one has ever seen before.

INDUSTRY LEADING CORROSION PROTECTIONWe utilise aircraft-grade aluminium alloys (highly corrosion resistant) for all of the major components of our roof rack system (with a layer of UV stable highly durable powder coat to provide additional protection). For all of our steel parts we utilise E-Coat (Electrophoretic Coating) to provide the very highest corrosion protection available for steel automotive parts, then we add a layer of UV stable powder coat on top for additional protection. All of the included fasteners are protected as well - black zinc plating, zinc flake coatings, black oxide coatings or sometimes we just choose to use stainless steel fasteners. Our aim is to keep your roof rack looking great for many years to come.

EASY TO INSTALLEasy bolt-on installation with no drilling. In addition, our bracketry is fully adjustable so it adapts to your roof.

TOP QUALITY FINISHING TOUCHESWe include all the details that matter. High tensile bolts for maximum strength. Wedge-Lock washers to create bolted joints that are extremely resistant to loosening (critical to combat loosening from off-roading vibrations). Anti-Seize for bolted joints that are resistant to seizing (important for a product that sits on your roof fully exposed to the elements). A Chief Products Shop Rag for all the dirty jobs around the garage. All packaged with extreme care to arrive safely and looking great.

We even include a few details you might not appreciate right away. For instance, if you’re installing lights, we provide channels in our mounting rails to run your wiring, (we even provide small holes for your zip ties, so you can hold your wiring up out of sight). -

No drilling or cutting required. Bolts to the roof using the existing roof nutserts provided by Toyota.Fitment confirmed on the following vehicles:2008 Toyota LandCruiser 2002009 Toyota LandCruiser 2002010 Toyota LandCruiser 2002010 Toyota LandCruiser 2002011 Toyota LandCruiser 2002012 Toyota LandCruiser 2002013 Toyota LandCruiser 2002014 Toyota LandCruiser 2002015 Toyota LandCruiser 2002016 Toyota LandCruiser 2002017 Toyota LandCruiser 2002018 Toyota LandCruiser 2002019 Toyota LandCruiser 2002020 Toyota LandCruiser 2002021 Toyota LandCruiser 200Compatible with the following products:This list is based on customer reports, Chief Products has not confirmed fitment of these products. This list will be updated regularly as customers report their experiences.INSTALLATION INSTRUCTIONS

J300 ROOF RACK

$999.99 AUD

Chief Products J300 Roof Rack provides the pinnacle of performance for roof rack systems on the J300 (Toyota LandCruiser 300, 2021-Current). It delivers industry-leading load ratings (150kg dynamic & 460kg static) and vehicle specific styling in a light-weight, low-profile design. Our Modular Roof Rack System provides an unrivalled amount of configurability. Customers can build the roof rack they want, and easily reconfigure it whenever their needs change. One configuration for around town (surfing-kayaking-mountain biking). Then easily change to another configuration for camping-expedition-overlanding (maximum gear, roof top tent, etc.). One roof rack; that can easily adapt to your needs.

-

Chief Products J300 Roof Rack provides the pinnacle of performance for roof rack systems on the J300 (Toyota LandCruiser 300, 2021-Current). It delivers industry-leading load ratings (150kg dynamic & 460kg static) and vehicle specific styling in a light-weight, low-profile design. Our Modular Roof Rack System provides an unrivalled amount of configurability. Customers can build the roof rack they want, and easily reconfigure it whenever their needs change. One configuration for around town (surfing-kayaking-mountain biking). Then easily change to another configuration for camping-expedition-overlanding (maximum gear, roof top tent, etc.). One roof rack; that can easily adapt to your needs.

We've utilised the latest manufacturing techniques and aircraft-grade aluminium alloys to keep the overall installed weight low and accomplish a degree of fit-and-finish you have to see in person to truly appreciate. The smooth top surface, low profile design and hidden fasteners have enabled us to deliver an extremely aerodynamic roof rack. Amazingly, even after thousands of kilometres of off-road driving, you won't hear any creaking or rattling. Best of all, we made it extremely easy to mount accessories - whether you're using t-nuts that slide the entire length of the Planks; or our industry-leading Tie-Down Plates that easily slide and clamp between the Planks. If you're looking for a top-quality place to carry extra gear on your next adventure, there's no doubt we've got you covered.

FEATURESMODULAR DESIGN (Mix-And-Match Components)GROUNDBREAKING CONFIGURABILITY (Easily Move & Change Components)HIGH-STRENGTH (Industry-Leading Load Ratings)TOP-QUALITY MATERIALS (Aircraft-Grade Aluminium Alloys + High-Strength Steel)INDUSTRY-LEADING DURABILITY (High-Strength + Corrosion Protection + UV Stable Coatings)INDUSTRY-LEADING CORROSION PROTECTION (Special Coatings, Materials & Hardware)EASILY MOUNT ACCESSORIES (Adjustable Planks, T-Nuts & Tie-Down Plates)PREMIUM ACCESSORIES (Top-Quality, Innovative & 3rd Party Compatibility)VEHICLE SPECIFIC STYLING (Mounting Rails & Aero)STEALTH (Low Wind Noise + No Creaking/Rattling + Unobstructed Sunroof + Stealth Air Dam)TOP QUALITY FASTENERS (Blackened Stainless or High-Tensile + Wedge-Lock Washers)FIT & FINISH (Precision Manufacturing + Unrivalled QC Processes)EASY INSTALLATION (Difficulty = 2/10)SPECIFICATIONS100kg DYNAMIC LOAD RATING (with 2x Half-Planks) 300kg STATIC LOAD RATING (with 2x Half-Planks) 150kg DYNAMIC LOAD RATING (with 2+ Planks) 460kg STATIC LOAD RATING (with 2+ Planks) 86mm OVERALL HEIGHT (above roof line) 25mm PLANK THICKNESS 28.34mm PLATFORM THICKNESS (fully assembled) 2160mm FULL PLATFORM LENGTH (fully assembled) 1246mm FULL PLATFORM WIDTH (fully assembled) 14.4kg INSTALLED WEIGHT --> Bare Bones 14.4kg INSTALLED WEIGHT --> Roof Top Tent [100-300kg] 18.3kg INSTALLED WEIGHT --> Roof Top Tent [150-460kg] 22.2kg INSTALLED WEIGHT --> Overland 34.5kg INSTALLED WEIGHT --> Safari 42.7kg INSTALLED WEIGHT --> Apex 11.1kg INSTALLED WEIGHT --> ((Build Your Own)) INCLUDESBARE BONES

1 J300 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Half-Planks) [1146mm] 1 ROOF RACK (4x Half-Plank End-Caps) 1 Installation Instructions ROOF TOP TENT [100-300kg]

1 J300 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Half-Planks) [1146mm] 1 ROOF RACK (4x Half-Plank End-Caps) 1 Installation Instructions ROOF TOP TENT [150-460kg]

1 J300 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Planks) [1146mm] 1 ROOF RACK (4x Plank End-Caps) 1 ROOF RACK (Roof Top Tent KIT) 1 Installation Instructions OVERLAND

SAFARI

1 J300 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 4 ROOF RACK (2x Planks) [1146mm] 4 ROOF RACK (4x Plank End-Caps) 1 ROOF RACK (2x Half-Planks) [1146mm] 1 ROOF RACK (4x Half-Plank End-Caps) 1 Installation Instructions APEX

1 J300 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 4 ROOF RACK (2x Planks) [1146mm] 1 ROOF RACK (2x Half-Planks) [1146mm] 1 ROOF RACK (Platform Frame) [8.5 Plank] 1 Installation Instructions ((BUILD YOUR OWN))

1 J300 ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 Installation Instructions EDITIONS* WARNING *

FOR MAXIMUM SAFETY DO NOT EXCEED MANUFACTURERS ROOF WEIGHT LIMITS. Our load ratings represent the maximum mechanical forces our roof rack system can withstand before failure. Our load ratings do not address vehicle safety during high-speed manoeuvres, or changes to vehicle dynamics caused by a higher centre of gravity.

* CAUTION *

For maximum safety, loads should be evenly distributed and properly secured to avoid shifting during transport. Before using your roof rack, it is important to familiarise yourself with the proper load securing techniques and be constantly safety oriented. Please note, all of our load ratings are based on an evenly distributed load. -

UNPRECEDENTED CONFIGURABILITYChoose how many Planks you want. Position your Planks wherever you want. Move your Planks easily, whenever you want. Choose if you want a frame around the outside. Choose how many Tie-Down Plates you want, and where you want them located. Configure your rack however you want. Numerous options. Numerous configurations.

MODULAR DESIGNOur modular engineering approach allow us to deliver a roof rack system that can be easily adapted to any situation. It also means you can upgrade-downgrade your roof rack any time your needs require.

HIGH-STRENGTHAll versions deliver industry leading load ratings. These ratings were independently tested and the test results are certified to comply with Australian Standard (AS 1235-2000) as well as international standards (ISO / PAS 11154 : 2009:2006) and (DIN 75302/02: 1991). During independent testing, our roof rack system successfully withstood 330kg of upward force, 600kg of forward force (including a special 20° off-axis test). To achieve our certification we needed to have less than 10mm of movement in our structure at the tested loads, we had 0.17mm!

One of the keys to our industry leading load ratings is our Mounting Rails. Not only do they transfer forces to the strongest points on the vehicle roof, they also utilise a boxed design that resists deformation at any singular point. This unique design element creates a 'mounting system’ that is much stronger than any of our competitors.

LOW WEIGHTWe utilise the latest manufacturing techniques and aircraft-grade aluminium alloys to deliver a roof rack system with an extremely high strength-to-weight ratio. This means our roof rack has an extremely low weight, while still being the very strongest on the market.

STEALTHChief Products roof racks are engineered to be extremely aerodynamic (smooth top surface, low profile design and hidden fasteners). These unique aerodynamic features make our roof racks extremely quiet for the majority of our customers. However, the more wind you have the more wind noise will increase. For customers that live in high-wind areas or regularly drive at high-speeds (120kmh+) we've developed a Stealth Air Dam (included with every set of Mounting Rails) that significantly reduces the noise caused by high-velocity air flows. Best of all, this wind noise performance improvement is accomplished utilising a product that mounts out-of-sight (ensuring it doesn't inhibit use of your rack, or obscure views out of your sunroof).

Our roof racks deliver an experience with no creaking, no rattling, and very low wind noise. We accomplish these amazing feats through a series of technologically advanced aerodynamic methods, along with some proven old school tech (rubber isolators).

LOW PROFILEOur roof racks are engineered to sit incredibly low at only 86mm above the roofline. We looked at mounting even closer to the vehicle, but during our real-world testing we found it was helpful to have a slight gap between the roof and the rack, so you can slip a hand underneath the rack to wash your roof.

UNOBSTRUCTED VIEWSIf your vehicle has a Sunroof, our roof rack won’t block your view (position your Planks wherever you want) so you can see and experience the beauty of the nature around you.

STYLEWe poured over every design detail to ensure the J300 Roof Rack would look great from every angle. Function was our primary aim, but we also studied every line and every proportion, paying close attention to how they integrate with the lines of the J300.

FIT & FINISHWe utilise advanced manufacturing techniques to achieve a degree of fit-and-finish you have to see in-person to truly appreciate.

SMOOTH TOP SURFACEThe top of our platform is completely smooth. No bolt heads sticking up, tie-down plates that sit completely flush and fasteners that are hidden from view.

EASILY MOUNT ACCESSORIESWe make it extremely easy to mount your accessories and bring your gear with you. We provide (2) full-length channels in each plank, enabling you to use T-Nuts that slide the entire length of the Planks. Even better, is our industry leading Tie-Down Plates and Anchor Points. They provide numerous mounting options and easily slide and clamp between the Planks.

TIE-DOWN PLATESOne of the primary usability goals for our roof racks, was that you could easily bolt/fasten/tie-down to the rack at almost any location. Our custom engineered Tie-Down Plates deliver on that goal. They clamp securely between the Planks in a way that allows them to easily move and fasten anywhere along the entire length of the Planks. The centre acts as an easy tie-down location, while the slots on either end hold captive T-Nuts (M6, M8 & M10) that can be used to fasten/bolt just about any accessory you can find. Best of all, when clamped in place they sit completely flush, providing a completely smooth top surface for your platform.

NEARLY UNLIMITED ACCESSORY MOUNTING LOCATIONSWe provide heaps of mounting locations so you can easily mount accessories anywhere. To achieve that goal, we've engineered Planks you can move wherever you need them. Then we've provided two full-length channels in each Plank for captive T-Nuts, allowing you to bolt/fasten to the Plank at any point along the entire length of the Plank. Finally, for maximum flexibility we've delivered Tie-Down Plates that can easily move and fasten anywhere along the entire length of the Planks.

COMPATIBLE WITH MOST ACCESSORIESIf the accessory uses M6, M8 or M10 bolts for mounting, it will probably work with our roof rack system. If not, one of our upcoming adapter kits should take care of business.

INNOVATIVE SUITE OF ACCESSORIESChief Products engineering team has already started work on several innovative accessories to further expand the functionality of our roof rack system. Taking advantage of our ground-up approach and modular design is allowing us to develop roof rack accessories that no one has ever seen before.

INDUSTRY LEADING CORROSION PROTECTIONWe utilise aircraft-grade aluminium alloys (highly corrosion resistant) for all of the major components of our roof rack system (with a layer of UV stable highly durable powder coat to provide additional protection). For all of our steel parts we utilise E-Coat (Electrophoretic Coating) to provide the very highest corrosion protection available for steel automotive parts, then we add a layer of UV stable powder coat on top for additional protection. All of the included fasteners are protected as well - black zinc plating, zinc flake coatings, black oxide coatings or sometimes we just choose to use stainless steel fasteners. Our aim is to keep your roof rack looking great for many years to come.

EASY TO INSTALLEasy bolt-on installation with no drilling. In addition, our bracketry is fully adjustable so it adapts to your roof.

TOP QUALITY FINISHING TOUCHESWe include all the details that matter. High tensile bolts for maximum strength. Wedge-Lock washers to create bolted joints that are extremely resistant to loosening (critical to combat loosening from off-roading vibrations). Anti-Seize for bolted joints that are resistant to seizing (important for a product that sits on your roof fully exposed to the elements). A Chief Products Shop Rag for all the dirty jobs around the garage. All packaged with extreme care to arrive safely and looking great.

We even include a few details you might not appreciate right away. For instance, if you’re installing lights, we provide channels in our mounting rails to run your wiring, (we even provide small holes for your zip ties, so you can hold your wiring up out of sight). -

No drilling or cutting required. Bolts to the roof using the existing roof nutserts provided by Toyota.Fitment confirmed on the following vehicles:2021 Toyota LandCruiser 3002022 Toyota LandCruiser 3002023 Toyota LandCruiser 3002024 Toyota LandCruiser 300Compatible with the following products:This list is based on customer reports, Chief Products has not confirmed fitment of these products. This list will be updated regularly as customers report their experiences.INSTALLATION INSTRUCTIONS

P375 ROOF RACK

$639.99 AUD

Chief Products P375 Roof Rack provides the pinnacle of performance for roof rack systems on the P375 (Ford Ranger, 2011-2021). It delivers industry-leading load ratings (150kg dynamic & 460kg static) and vehicle specific styling in a light-weight, low-profile design. Our Modular Roof Rack System provides an unrivalled amount of configurability. Customers can build the roof rack they want, and easily reconfigure it whenever their needs change. One configuration for around town (surfing-kayaking-mountain biking). Then easily change to another configuration for camping-expedition-overlanding (maximum gear, roof top tent, etc.). One roof rack; that can easily adapt to your needs.

-

Chief Products P375 Roof Rack provides the pinnacle of performance for roof rack systems on the P375 (Ford Ranger, 2011-2021). It delivers industry-leading load ratings (150kg dynamic & 460kg static) and vehicle specific styling in a light-weight, low-profile design. Our Modular Roof Rack System provides an unrivalled amount of configurability. Customers can build the roof rack they want, and easily reconfigure it whenever their needs change. One configuration for around town (surfing-kayaking-mountain biking). Then easily change to another configuration for camping-expedition-overlanding (maximum gear, roof top tent, etc.). One roof rack; that can easily adapt to your needs.

We've utilised the latest manufacturing techniques and aircraft-grade aluminium alloys to keep the overall installed weight low and accomplish a degree of fit-and-finish you have to see in person to truly appreciate. The smooth top surface, low profile design and hidden fasteners have enabled us to deliver an extremely aerodynamic roof rack. Amazingly, even after thousands of kilometres of off-road driving, you won't hear any creaking or rattling. Best of all, we made it extremely easy to mount accessories - whether you're using t-nuts that slide the entire length of the Planks; or our industry-leading Tie-Down Plates that easily slide and clamp between the Planks. If you're looking for a top-quality place to carry extra gear on your next adventure, there's no doubt we've got you covered.

FEATURESMODULAR DESIGN (Mix-And-Match Components)GROUNDBREAKING CONFIGURABILITY (Easily Move & Change Components)HIGH-STRENGTH (Industry-Leading Load Ratings)TOP-QUALITY MATERIALS (Aircraft-Grade Aluminium Alloys + High-Strength Steel)INDUSTRY-LEADING DURABILITY (High-Strength + Corrosion Protection + UV Stable Coatings)INDUSTRY-LEADING CORROSION PROTECTION (Special Coatings, Materials & Hardware)EASILY MOUNT ACCESSORIES (Adjustable Planks, T-Nuts & Tie-Down Plates)PREMIUM ACCESSORIES (Top-Quality, Innovative & 3rd Party Compatibility)VEHICLE SPECIFIC STYLING (Mounting Rails & Aero)STEALTH (Low Wind Noise + No Creaking/Rattling + Unobstructed Sunroof + Stealth Air Dam)TOP QUALITY FASTENERS (Blackened Stainless or High-Tensile + Wedge-Lock Washers)FIT & FINISH (Precision Manufacturing + Unrivalled QC Processes)EASY INSTALLATION (Difficulty = 2/10)SPECIFICATIONS100kg DYNAMIC LOAD RATING (with 2x Half-Planks) 300kg STATIC LOAD RATING (with 2x Half-Planks) 150kg DYNAMIC LOAD RATING (with 2+ Planks) 460kg STATIC LOAD RATING (with 2+ Planks) 86mm OVERALL HEIGHT (above roof line) 25mm PLANK THICKNESS 28.34mm PLATFORM THICKNESS (fully assembled) 1490mm FULL PLATFORM LENGTH (fully assembled) 1246mm FULL PLATFORM WIDTH (fully assembled) 10.4kg INSTALLED WEIGHT --> Bare Bones 10.4kg INSTALLED WEIGHT --> Roof Top Text [100-300kg] 14.3kg INSTALLED WEIGHT --> Roof Top Text [150-460kg] 18.2kg INSTALLED WEIGHT --> Overland 24.6kg INSTALLED WEIGHT --> Safari 29.0kg INSTALLED WEIGHT --> Apex 7.1kg INSTALLED WEIGHT --> ((Build Your Own)) INCLUDESBARE BONES

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Half-Planks) [1146mm] 1 ROOF RACK (4x Half-Plank End-Caps) 1 Installation Instructions ROOF TOP TENT [100-300kg]

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Half-Planks) [1146mm] 1 ROOF RACK (4x Half-Plank End-Caps) 1 Installation Instructions ROOF TOP TENT [150-460kg]

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Planks) [1146mm] 1 ROOF RACK (4x Plank End-Caps) 1 ROOF RACK (Roof Top Tent KIT) 1 Installation Instructions OVERLAND

SAFARI

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 3 ROOF RACK (2x Planks) [1146mm] 3 ROOF RACK (4x Plank End-Caps) 1 Installation Instructions APEX

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 3 ROOF RACK (2x Planks) [1146mm] 1 ROOF RACK (Platform Frame) [6 Plank] 1 Installation Instructions ((BUILD YOUR OWN))

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 Installation Instructions EDITIONS* WARNING *

FOR MAXIMUM SAFETY DO NOT EXCEED MANUFACTURERS ROOF WEIGHT LIMITS. Our load ratings represent the maximum mechanical forces our roof rack system can withstand before failure. Our load ratings do not address vehicle safety during high-speed manoeuvres, or changes to vehicle dynamics caused by a higher centre of gravity.

* CAUTION *

For maximum safety, loads should be evenly distributed and properly secured to avoid shifting during transport. Before using your roof rack, it is important to familiarise yourself with the proper load securing techniques and be constantly safety oriented. Please note, all of our load ratings are based on an evenly distributed load. -

UNPRECEDENTED CONFIGURABILITYChoose how many Planks you want. Position your Planks wherever you want. Move your Planks easily, whenever you want. Choose if you want a frame around the outside. Choose how many Tie-Down Plates you want, and where you want them located. Configure your rack however you want. Numerous options. Numerous configurations.

MODULAR DESIGNOur modular engineering approach allow us to deliver a roof rack system that can be easily adapted to any situation. It also means you can upgrade-downgrade your roof rack any time your needs require.

HIGH-STRENGTHAll versions deliver industry leading load ratings. These ratings were independently tested and the test results are certified to comply with Australian Standard (AS 1235-2000) as well as international standards (ISO / PAS 11154 : 2009:2006) and (DIN 75302/02: 1991). During independent testing, our roof rack system successfully withstood 330kg of upward force, 600kg of forward force (including a special 20° off-axis test). To achieve our certification we needed to have less than 10mm of movement in our structure at the tested loads, we had 0.17mm!

One of the keys to our industry leading load ratings is our Mounting Rails. Not only do they transfer forces to the strongest points on the vehicle roof, they also utilise a boxed design that resists deformation at any singular point. This unique design element creates a 'mounting system’ that is much stronger than any of our competitors.

LOW WEIGHTWe utilise the latest manufacturing techniques and aircraft-grade aluminium alloys to deliver a roof rack system with an extremely high strength-to-weight ratio. This means our roof rack has an extremely low weight, while still being the very strongest on the market.

STEALTHChief Products roof racks are engineered to be extremely aerodynamic (smooth top surface, low profile design and hidden fasteners). These unique aerodynamic features make our roof racks extremely quiet for the majority of our customers. However, the more wind you have the more wind noise will increase. For customers that live in high-wind areas or regularly drive at high-speeds (120kmh+) we've developed a Stealth Air Dam (included with every set of Mounting Rails) that significantly reduces the noise caused by high-velocity air flows. Best of all, this wind noise performance improvement is accomplished utilising a product that mounts out-of-sight (ensuring it doesn't inhibit use of your rack, or obscure views out of your sunroof).

Our roof racks deliver an experience with no creaking, no rattling, and very low wind noise. We accomplish these amazing feats through a series of technologically advanced aerodynamic methods, along with some proven old school tech (rubber isolators).

LOW PROFILEOur roof racks are engineered to sit incredibly low at only 86mm above the roofline. We looked at mounting even closer to the vehicle, but during our real-world testing we found it was helpful to have a slight gap between the roof and the rack, so you can slip a hand underneath the rack to wash your roof.

UNOBSTRUCTED VIEWSIf your vehicle has a Sunroof, our roof rack won’t block your view (position your Planks wherever you want) so you can see and experience the beauty of the nature around you.

STYLEWe poured over every design detail to ensure the P375 Roof Rack would look great from every angle. Function was our primary aim, but we also studied every line and every proportion, paying close attention to how they integrate with the lines of the P375.

FIT & FINISHWe utilise advanced manufacturing techniques to achieve a degree of fit-and-finish you have to see in-person to truly appreciate.

SMOOTH TOP SURFACEThe top of our platform is completely smooth. No bolt heads sticking up, tie-down plates that sit completely flush and fasteners that are hidden from view.

EASILY MOUNT ACCESSORIESWe make it extremely easy to mount your accessories and bring your gear with you. We provide (2) full-length channels in each plank, enabling you to use T-Nuts that slide the entire length of the Planks. Even better, is our industry leading Tie-Down Plates and Anchor Points. They provide numerous mounting options and easily slide and clamp between the Planks.

TIE-DOWN PLATESOne of the primary usability goals for our roof racks, was that you could easily bolt/fasten/tie-down to the rack at almost any location. Our custom engineered Tie-Down Plates deliver on that goal. They clamp securely between the Planks in a way that allows them to easily move and fasten anywhere along the entire length of the Planks. The centre acts as an easy tie-down location, while the slots on either end hold captive T-Nuts (M6, M8 & M10) that can be used to fasten/bolt just about any accessory you can find. Best of all, when clamped in place they sit completely flush, providing a completely smooth top surface for your platform.

NEARLY UNLIMITED ACCESSORY MOUNTING LOCATIONSWe provide heaps of mounting locations so you can easily mount accessories anywhere. To achieve that goal, we've engineered Planks you can move wherever you need them. Then we've provided two full-length channels in each Plank for captive T-Nuts, allowing you to bolt/fasten to the Plank at any point along the entire length of the Plank. Finally, for maximum flexibility we've delivered Tie-Down Plates that can easily move and fasten anywhere along the entire length of the Planks.

COMPATIBLE WITH MOST ACCESSORIESIf the accessory uses M6, M8 or M10 bolts for mounting, it will probably work with our roof rack system. If not, one of our upcoming adapter kits should take care of business.

INNOVATIVE SUITE OF ACCESSORIESChief Products engineering team has already started work on several innovative accessories to further expand the functionality of our roof rack system. Taking advantage of our ground-up approach and modular design is allowing us to develop roof rack accessories that no one has ever seen before.

INDUSTRY LEADING CORROSION PROTECTIONWe utilise aircraft-grade aluminium alloys (highly corrosion resistant) for all of the major components of our roof rack system (with a layer of UV stable highly durable powder coat to provide additional protection). For all of our steel parts we utilise E-Coat (Electrophoretic Coating) to provide the very highest corrosion protection available for steel automotive parts, then we add a layer of UV stable powder coat on top for additional protection. All of the included fasteners are protected as well - black zinc plating, zinc flake coatings, black oxide coatings or sometimes we just choose to use stainless steel fasteners. Our aim is to keep your roof rack looking great for many years to come.

EASY TO INSTALLEasy bolt-on installation with no drilling. In addition, our bracketry is fully adjustable so it adapts to your roof.

TOP QUALITY FINISHING TOUCHESWe include all the details that matter. High tensile bolts for maximum strength. Wedge-Lock washers to create bolted joints that are extremely resistant to loosening (critical to combat loosening from off-roading vibrations). Anti-Seize for bolted joints that are resistant to seizing (important for a product that sits on your roof fully exposed to the elements). A Chief Products Shop Rag for all the dirty jobs around the garage. All packaged with extreme care to arrive safely and looking great.

We even include a few details you might not appreciate right away. For instance, if you’re installing lights, we provide channels in our mounting rails to run your wiring, (we even provide small holes for your zip ties, so you can hold your wiring up out of sight). -

Requires drilling (8) holes in the roof gutter to install stainless steel nutserts.Fitment confirmed on the following vehicles:2011 Ford Ranger2012 Ford Ranger2013 Ford Ranger2014 Ford Ranger2015 Ford Ranger2016 Ford Ranger2017 Ford Ranger2018 Ford Ranger2019 Ford Ranger2020 Ford Ranger2021 Ford RangerCompatible with the following products:This list is based on customer reports, Chief Products has not confirmed fitment of these products. This list will be updated regularly as customers report their experiences.INSTALLATION INSTRUCTIONS

P703 ROOF RACK

$639.99 AUD

Chief Products P703 Roof Rack provides the pinnacle of performance for roof rack systems on the P703 (Ford Ranger, 2022-Current). It delivers industry-leading load ratings (150kg dynamic & 460kg static) and vehicle specific styling in a light-weight, low-profile design. Our Modular Roof Rack System provides an unrivalled amount of configurability. Customers can build the roof rack they want, and easily reconfigure it whenever their needs change. One configuration for around town (surfing-kayaking-mountain biking). Then easily change to another configuration for camping-expedition-overlanding (maximum gear, roof top tent, etc.). One roof rack; that can easily adapt to your needs.

-

Chief Products P703 Roof Rack provides the pinnacle of performance for roof rack systems on the P703 (Ford Ranger, 2022-Current). It delivers industry-leading load ratings (150kg dynamic & 460kg static) and vehicle specific styling in a light-weight, low-profile design. Our Modular Roof Rack System provides an unrivalled amount of configurability. Customers can build the roof rack they want, and easily reconfigure it whenever their needs change. One configuration for around town (surfing-kayaking-mountain biking). Then easily change to another configuration for camping-expedition-overlanding (maximum gear, roof top tent, etc.). One roof rack; that can easily adapt to your needs.

We've utilised the latest manufacturing techniques and aircraft-grade aluminium alloys to keep the overall installed weight low and accomplish a degree of fit-and-finish you have to see in person to truly appreciate. The smooth top surface, low profile design and hidden fasteners have enabled us to deliver an extremely aerodynamic roof rack. Amazingly, even after thousands of kilometres of off-road driving, you won't hear any creaking or rattling. Best of all, we made it extremely easy to mount accessories - whether you're using t-nuts that slide the entire length of the Planks; or our industry-leading Tie-Down Plates that easily slide and clamp between the Planks. If you're looking for a top-quality place to carry extra gear on your next adventure, there's no doubt we've got you covered.

FEATURESMODULAR DESIGN (Mix-And-Match Components)GROUNDBREAKING CONFIGURABILITY (Easily Move & Change Components)HIGH-STRENGTH (Industry-Leading Load Ratings)TOP-QUALITY MATERIALS (Aircraft-Grade Aluminium Alloys + High-Strength Steel)INDUSTRY-LEADING DURABILITY (High-Strength + Corrosion Protection + UV Stable Coatings)INDUSTRY-LEADING CORROSION PROTECTION (Special Coatings, Materials & Hardware)EASILY MOUNT ACCESSORIES (Adjustable Planks, T-Nuts & Tie-Down Plates)PREMIUM ACCESSORIES (Top-Quality, Innovative & 3rd Party Compatibility)VEHICLE SPECIFIC STYLING (Mounting Rails & Aero)STEALTH (Low Wind Noise + No Creaking/Rattling + Unobstructed Sunroof + Stealth Air Dam)TOP QUALITY FASTENERS (Blackened Stainless or High-Tensile + Wedge-Lock Washers)FIT & FINISH (Precision Manufacturing + Unrivalled QC Processes)EASY INSTALLATION (Difficulty = 2/10)SPECIFICATIONS100kg DYNAMIC LOAD RATING (with 2x Half-Planks) 300kg STATIC LOAD RATING (with 2x Half-Planks) 150kg DYNAMIC LOAD RATING (with 2+ Planks) 460kg STATIC LOAD RATING (with 2+ Planks) 86mm OVERALL HEIGHT (above roof line) 25mm PLANK THICKNESS 28.34mm PLATFORM THICKNESS (fully assembled) 1490mm FULL PLATFORM LENGTH (fully assembled) 1246mm FULL PLATFORM WIDTH (fully assembled) 10.4kg INSTALLED WEIGHT --> Bare Bones 10.4kg INSTALLED WEIGHT --> Roof Top Tent [100-300kg] 14.3kg INSTALLED WEIGHT --> Roof Top Tent [150-460kg] 18.2kg INSTALLED WEIGHT --> Overland 24.6kg INSTALLED WEIGHT --> Safari 29.0kg INSTALLED WEIGHT --> Apex 7.1kg INSTALLED WEIGHT --> ((Build Your Own)) INCLUDESBARE BONES

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (2x Half-Planks) [1146mm] 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (4x Half-Plank End-Caps) 1 Installation Instructions ROOF TOP TENT [100-300kg]

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Half-Planks) [1146mm] 1 ROOF RACK (4x Half-Plank End-Caps) 1 Installation Instructions ROOF TOP TENT [150-460kg]

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 ROOF RACK (2x Planks) [1146mm] 1 ROOF RACK (4x Plank End-Caps) 1 ROOF RACK (Roof Top Tent KIT) 1 Installation Instructions OVERLAND

SAFARI

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 3 ROOF RACK (2x Planks) [1146mm] 3 ROOF RACK (4x Plank End-Caps) 1 Installation Instructions APEX

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 3 ROOF RACK (2x Planks) [1146mm] 1 ROOF RACK (Platform Frame) [6 Plank] 1 Installation Instructions ((BUILD YOUR OWN))

1 P375-P703-AM2G-UP-UR ROOF RACK (Mounting Rails) 1 ROOF RACK (Stealth Air Dam) 1 Installation Instructions EDITIONS* WARNING *

FOR MAXIMUM SAFETY DO NOT EXCEED MANUFACTURERS ROOF WEIGHT LIMITS. Our load ratings represent the maximum mechanical forces our roof rack system can withstand before failure. Our load ratings do not address vehicle safety during high-speed manoeuvres, or changes to vehicle dynamics caused by a higher centre of gravity.

* CAUTION *

For maximum safety, loads should be evenly distributed and properly secured to avoid shifting during transport. Before using your roof rack, it is important to familiarise yourself with the proper load securing techniques and be constantly safety oriented. Please note, all of our load ratings are based on an evenly distributed load. -

UNPRECEDENTED CONFIGURABILITYChoose how many Planks you want. Position your Planks wherever you want. Move your Planks easily, whenever you want. Choose if you want a frame around the outside. Choose how many Tie-Down Plates you want, and where you want them located. Configure your rack however you want. Numerous options. Numerous configurations.

MODULAR DESIGNOur modular engineering approach allow us to deliver a roof rack system that can be easily adapted to any situation. It also means you can upgrade-downgrade your roof rack any time your needs require.

HIGH-STRENGTHAll versions deliver industry leading load ratings. These ratings were independently tested and the test results are certified to comply with Australian Standard (AS 1235-2000) as well as international standards (ISO / PAS 11154 : 2009:2006) and (DIN 75302/02: 1991). During independent testing, our roof rack system successfully withstood 330kg of upward force, 600kg of forward force (including a special 20° off-axis test). To achieve our certification we needed to have less than 10mm of movement in our structure at the tested loads, we had 0.17mm!

One of the keys to our industry leading load ratings is our Mounting Rails. Not only do they transfer forces to the strongest points on the vehicle roof, they also utilise a boxed design that resists deformation at any singular point. This unique design element creates a 'mounting system’ that is much stronger than any of our competitors.

LOW WEIGHTWe utilise the latest manufacturing techniques and aircraft-grade aluminium alloys to deliver a roof rack system with an extremely high strength-to-weight ratio. This means our roof rack has an extremely low weight, while still being the very strongest on the market.

STEALTHChief Products roof racks are engineered to be extremely aerodynamic (smooth top surface, low profile design and hidden fasteners). These unique aerodynamic features make our roof racks extremely quiet for the majority of our customers. However, the more wind you have the more wind noise will increase. For customers that live in high-wind areas or regularly drive at high-speeds (120kmh+) we've developed a Stealth Air Dam (included with every set of Mounting Rails) that significantly reduces the noise caused by high-velocity air flows. Best of all, this wind noise performance improvement is accomplished utilising a product that mounts out-of-sight (ensuring it doesn't inhibit use of your rack, or obscure views out of your sunroof).